- Out-of-Stock

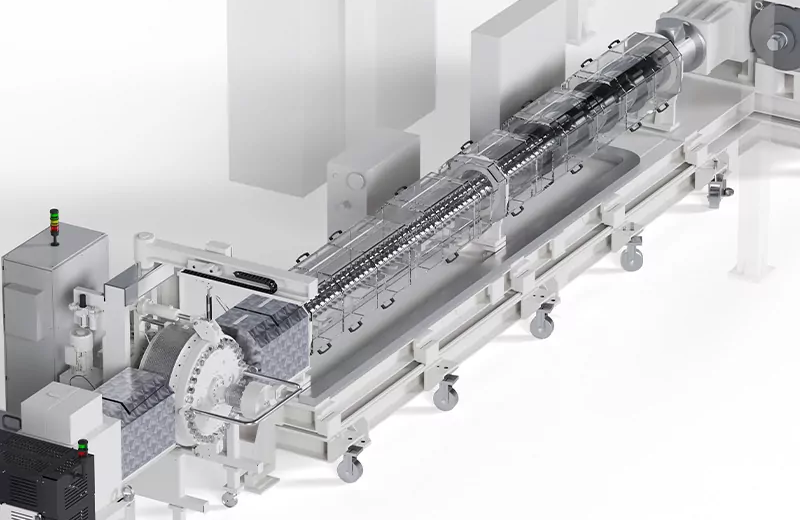

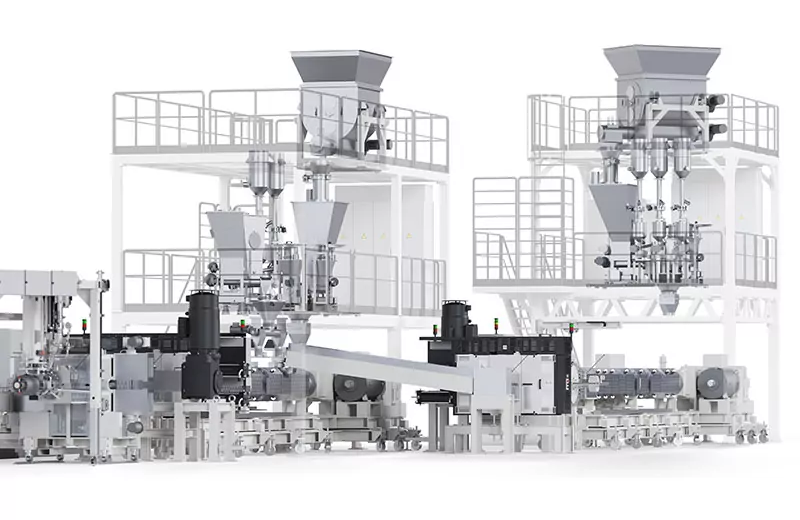

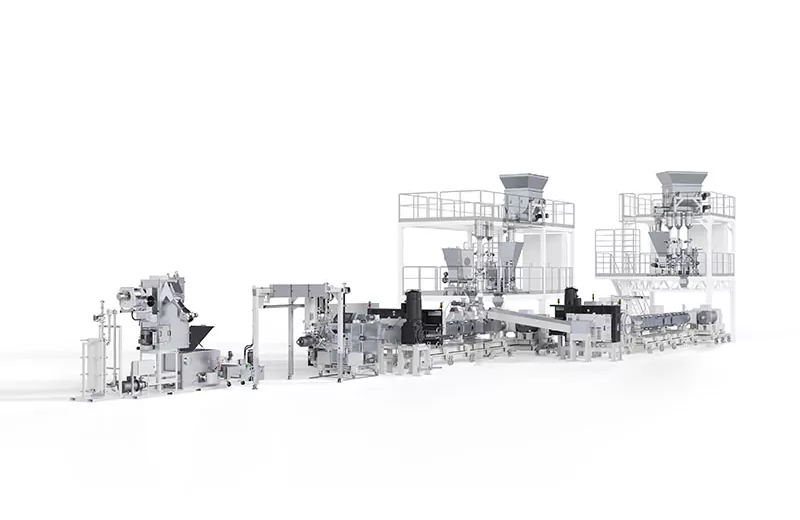

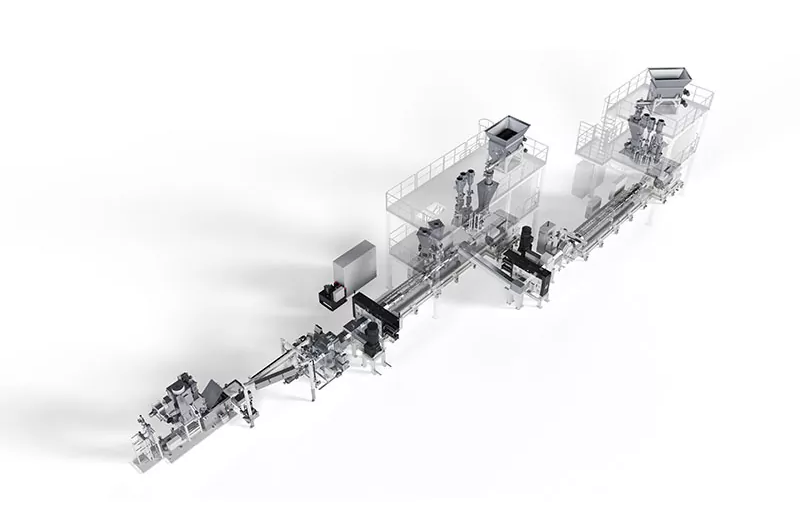

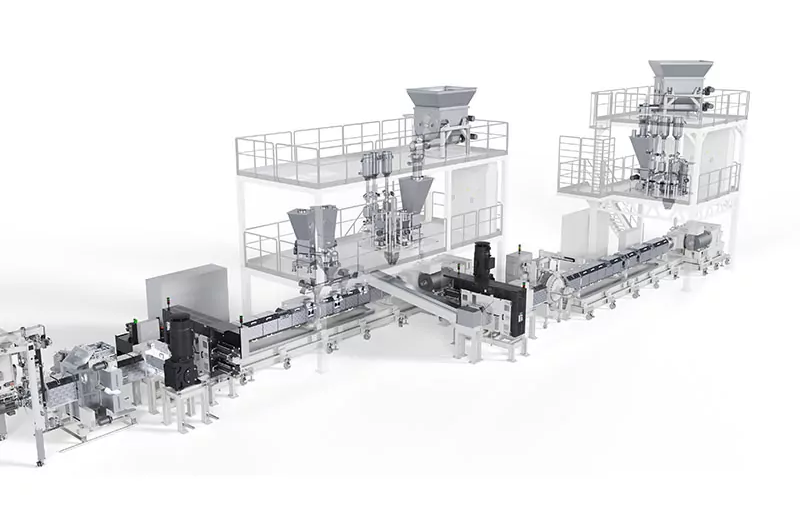

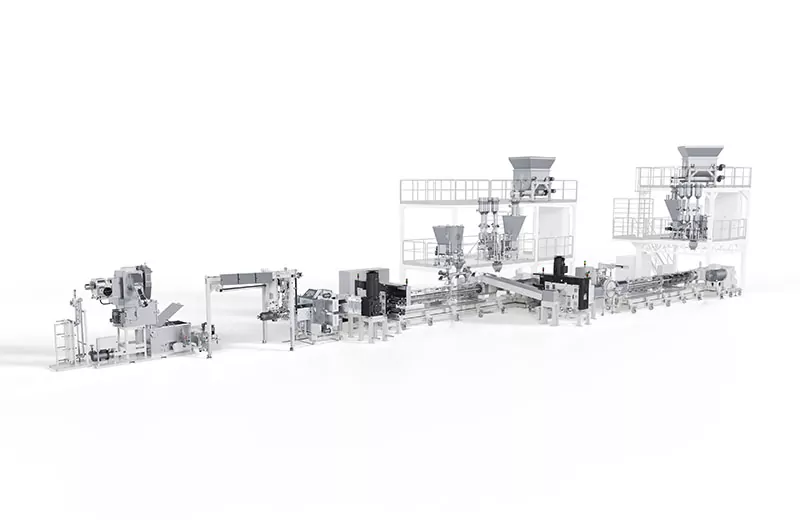

Solution with the highest technological content: a pair of co-rotating twin screws working in “cascade” mode, with a double dosing station and lateral feeders for adding new materials.

Line adaptable to any condition, to suit the many characteristics of the input material.

Thanks to the cascade configuration, the line allows a filtration strategy that can be adapted to the contamination of the material or to the flexibility of the equipment.

Perfect blending of seemingly incompatible polymer structures.

Gentle process due to the low friction level of the melt.

Tandem system that allows a double degassing action, with an extremely efficient effect in removing volatile components, humidity and in managing heavily inked materials.

TWIN TANDEM PCR 105

Capacity 650 – 1.000 kg/h | 1433.0-2204.6lb/h

TWIN TANDEM PCR 135

Capacity 1.000 – 2.000 kg/h | 2425.0-4409.0lb/h

TWIN TANDEM PCR 170

Capacity 2.100 – 3.000 kg/h | 4629,7-6613,9 lb/h