- Out-of-Stock

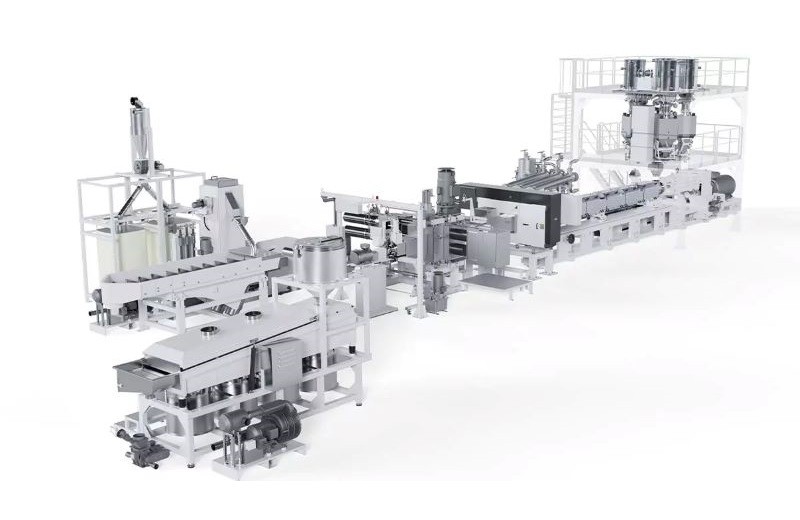

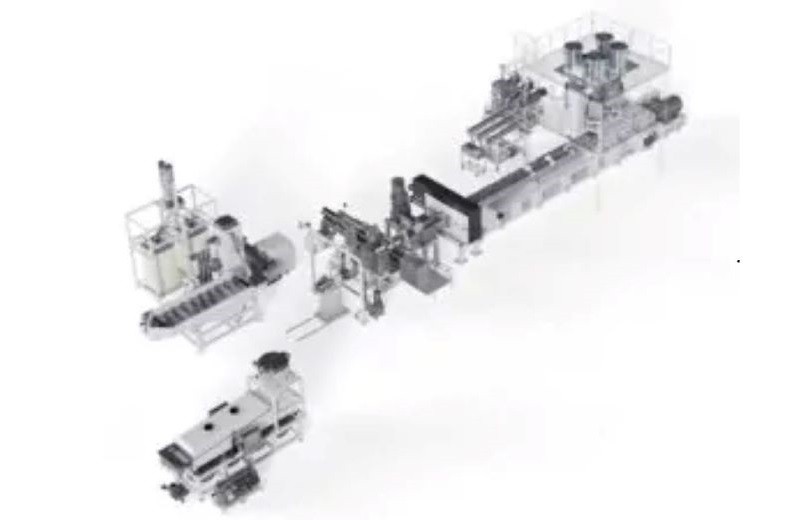

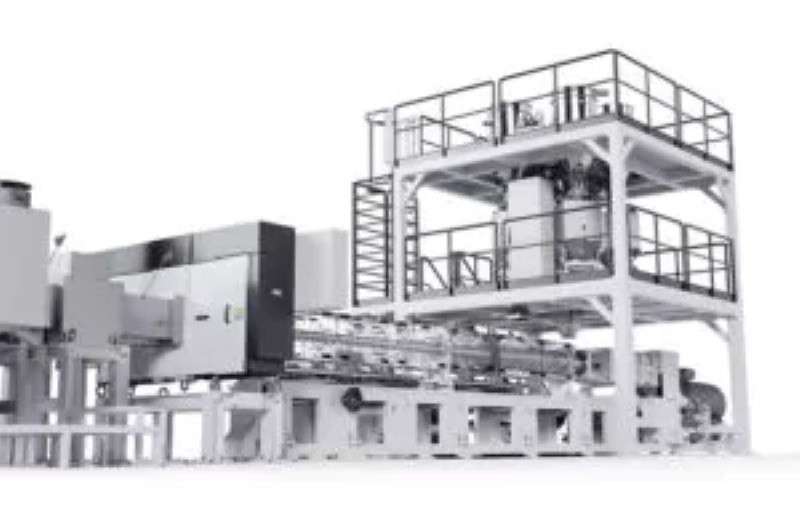

Bandera’s long experience in the world of PET, with over 300 flake treatment plants worldwide, has allowed the development of a technology not only capable of delivering a quality granule, but also of redefining new market standards, offering plants with high capacities and with a minimum kWh/kg energy incidence for being able to prime economies of scale to ensure a better return on investment.

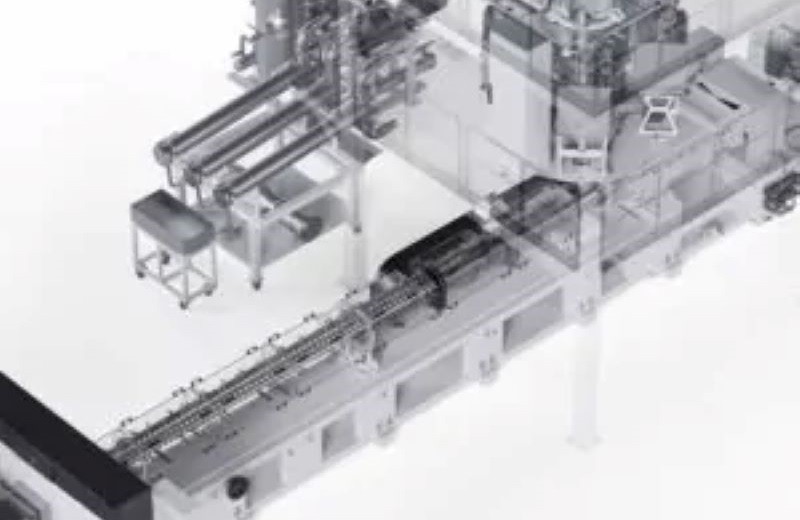

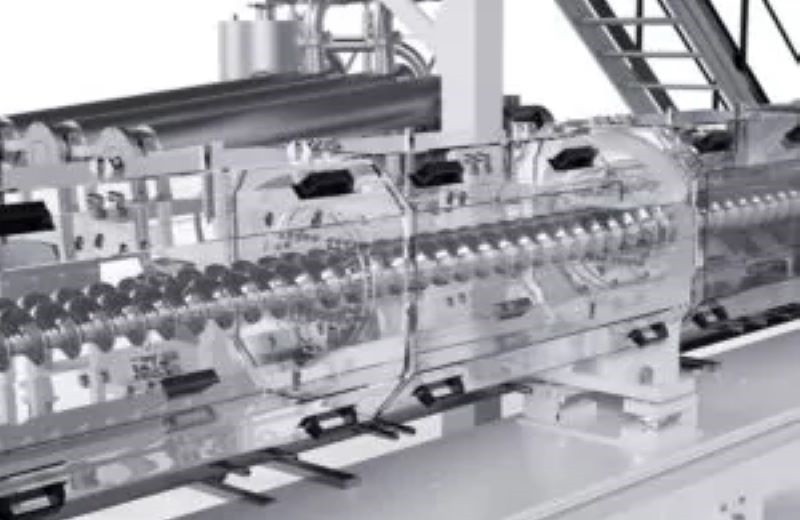

The patent HVTSE®,patent is based on the co-rotating twin-screw extrusion technology, with a length ratio of 52 diameters, designed to ensure a very high degassing efficiency while minimizing material degradation.

No pre-treatments, low pressures in the extrusion chamber and low level of shear stress drastically reduce the energy demand, up to a specific consumption of 0.21 kWh/kg (excluding chillers and material handling).

No pre-treatment on the flake (densification or drying), with zero risk of yellowing and the need to use dyes as correctors.

Production up to 5 t/h with a single extruder.

HVTSE® gentle process minimizes the stress the material is subjected to, preserving the integrity of the polymer chains whose breakage would generate IV drop.

Extreme flexibility in the use of recycled materials available on the market (post- consumer from bottles and/or trays) and deriving from internal industrial waste (trims, starter reels, sprues, etc.).

TwinPET 1600

Capacity 1.100 – 1.600 kg/h

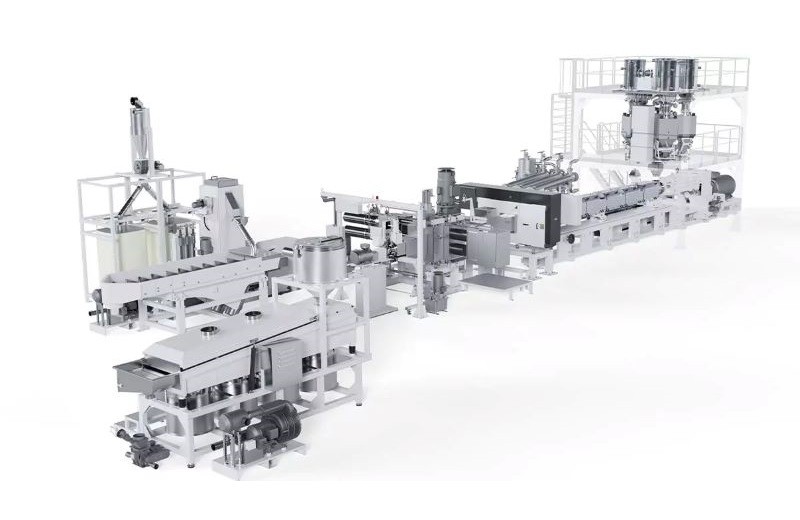

TwinPET 2300

Capacity 1.700 – 2.300 kg/h

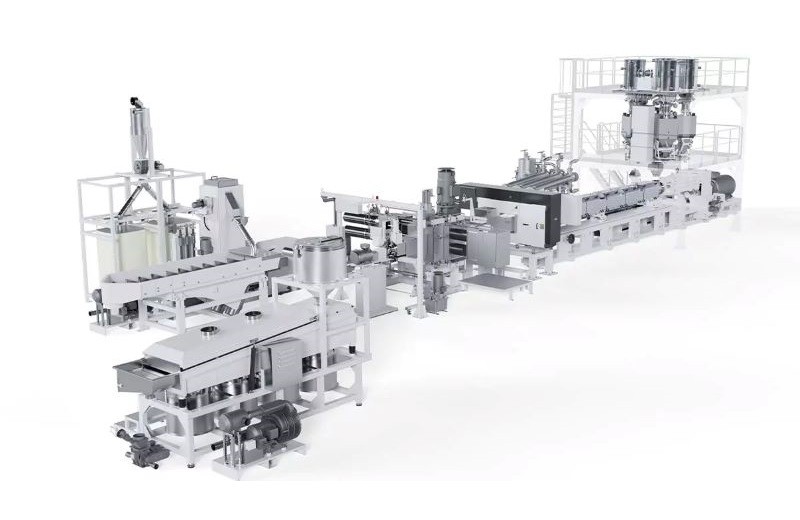

TwinPET 3000

Capacity 2.400 – 3.000 kg/h

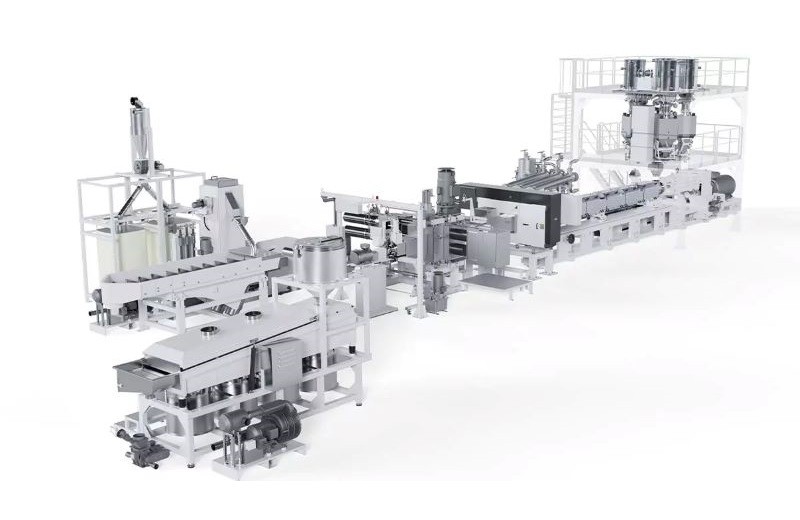

TwinPET 4000

Capacity 3.100 – 4.000 kg/h

TwinPET 5000

Capacity 4.100 – 5.000 kg/h