- Out-of-Stock

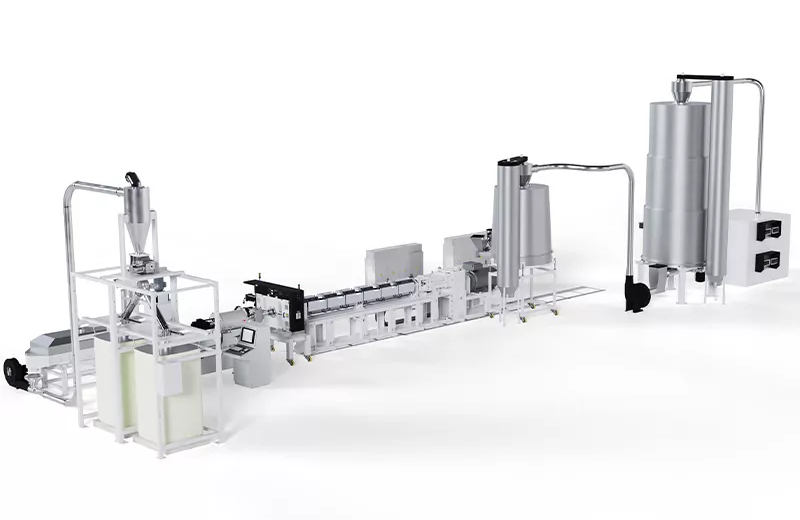

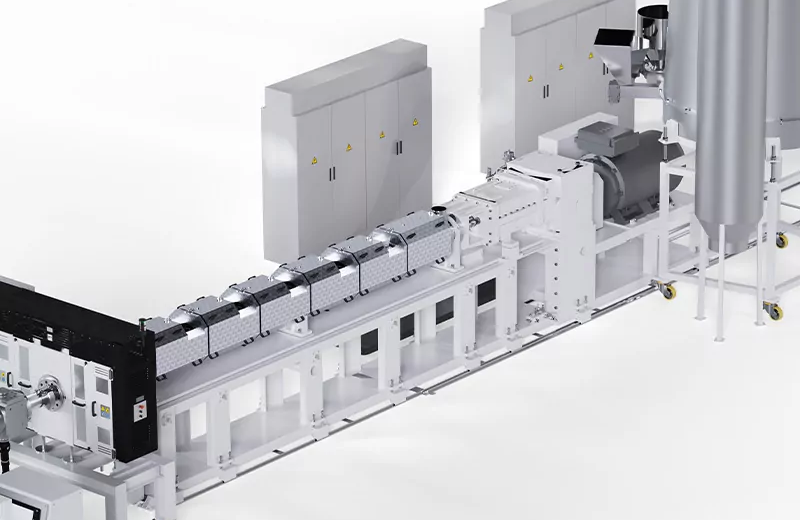

The Bandera co-rotating system is able to reprocess up to 100% of waste and convert it into a product with high added value, not dissimilar from the raw material. This system is particularly recommended for the recovery of technical films (cross-linked) or barrier multi-material films (PE/PA/EVOH).

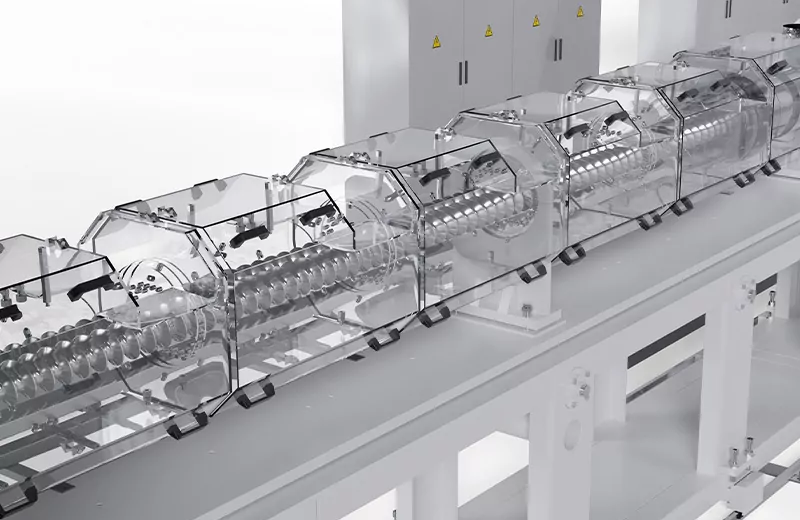

No pre-treatment on the material

The forced introduction into the extrusion chamber, without a previous pre-treatment (e.g. densification), avoids the possibility to run into deterioration of the product. Particularly recommended for films containing thermo-sensitive resins.

Self-cleaning screws

With the unique profile designed by Bandera the screws are self-cleaning, thus avoiding stagnation which would inevitably lead to black spots.

Short residence times

They involve the significant reduction of thermal and mechanical stress on the material.

Twin PIR® 70

Flow rate 150-300 kg/h – 330.7-661.4 lb/h

Twin PIR® 85

Flow rate 350-600 kg/h – 771.6-1322.8 lb/h

Twin PIR® 105

Flow rate 650-1.000 kg/h – 1433.0-2204.6 lb/h

Twin PIR® 135

Flow rate 1.100-1.500 kg/h – 2425.0-3307.0 lb/h