- Out-of-Stock

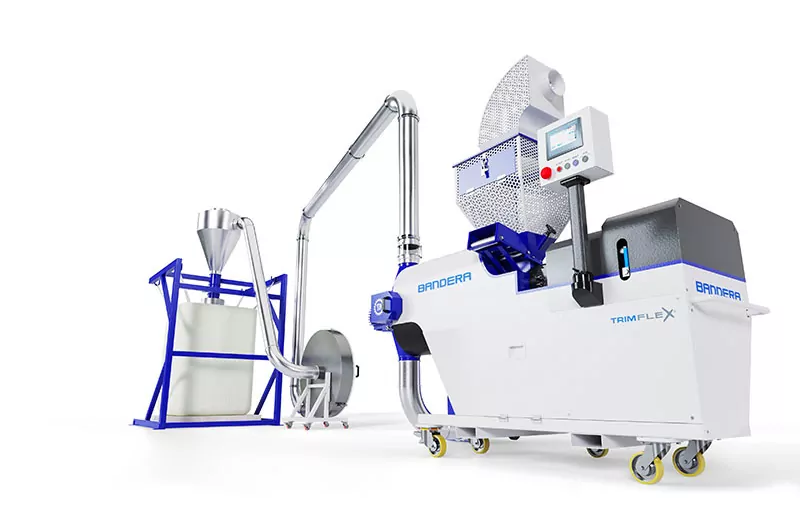

100 % trim recovery performed in-line in blown film and cast film extrusion processes. Simple, smart, integrated and automated unit with a capacity of up to 80 kg/h.

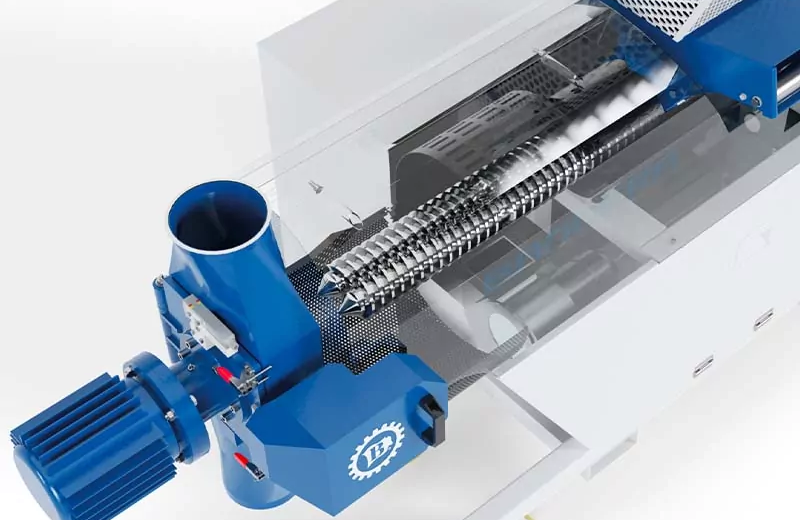

Perfect mixing of multilayer materials thanks to double screw

Optimal gelling and careful mixing of the material thanks to the innovative screw-cylinder profile International Patent Pending

Spontaneous material feeding thanks to the design and rotation towards the center of the screws

Technologically advanced small units

Contemporary feeding of small reels and trimmings thanks to the two hopper openings

Trim FLEX® i61

Maximum flow rate 40 kg/h – 88.0 lb/h

Trim FLEX® i72

Maximum flow rate 80 kg/h – 176.0 lb/h