- Out-of-Stock

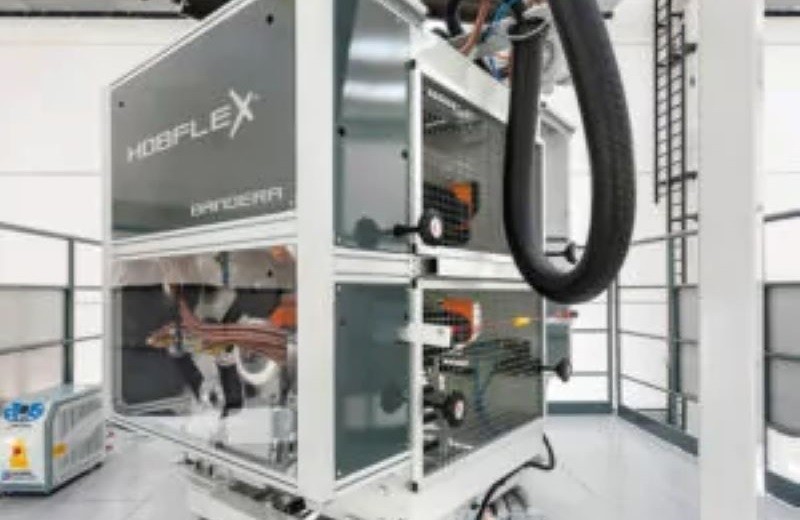

Besides the excellent mechanical features in terms of weldability, processability and printability, our competence in this sector is oriented to minimized film thickness in order to maximize production capacity – up to 450 kg/h (according to HDB size). A significant output increase is achieved thanks to the integration of innovative technical solutions, such as the triple-flow cooling ring combined with the unique design of Bandera® Extrusion heads, the film cooling system – ensuring an improved creaseless film surface – up to the integrated thickness control and the fully-automated winding station.

Sectors: Industry

Initial focusing on offering Extrusion lines pursuing excellent mechanical characteristics, weldability, processability and printability, today the market trends require minimized film thickness aimed at maximizing product capacity up to 450 kg/h (based on HDB size).

Bandera has taken on this new challenge finding out specific solutions to meet its customers’ individual needs, thus confirming – once again – its outstanding strong customer satisfaction orientation.

Specifically, innovative solutions have been applied in each and every Extrusion line section.

The most outstanding ones are: